The energy-saving

digester agitator Biobull®

TECHNICAL PROPERTIES

| Type | Power rating | Current rating | Nominal speed | Thrust force | Circulating rate * |

|---|---|---|---|---|---|

| kW | A | rpm | N | m³/h | |

| BIOE 114 G | 11 | 21.5 | 38 | approx. 7,000 | approx. 22,600 |

| Motor 400 V, rated frequency 50 Hz, index of protection IP 54 | * Circulating rate according to ISO 21630:2007 |

DIMENSIONS AND WEIGHTS

| Propeller diameter | 2,650 mm, 1,500 mm or as required |

|---|---|

| Required wall opening | Shaft lining 600 x 600 mm or core hole 450 mm |

| Required cover opening to lift the agitator shaft | 2,200 x 650 mm |

| Total weight | approx. 1,100 - 1,500 kg depending on the version |

The height of the bottom-bearing bracket and the length of the agitator shaft are determined by the tank dimensions.

MATERIALS

| Gas-flushed parts in the tank | Stainless steel 1.4571 (V4A) |

|---|---|

| Parts outside the tank | Galvanized, painted or coated |

| Bottom bearing | Silicon carbide mechanical seal |

| Propeller (dia. 2,650 mm) | High-strength, wear-resistant polymer with steel core |

| Propeller (dia. 1,500 mm) | Stainless steel 1.4301 (V2A) |

SAFETY

- ATEX, IECEx and UL/CSA-certified version for use in explosion protection zones 1 and 2

- Frequency inverter with parameterised safety software (torque limiting, coupling break detection, etc.)

- "streisal SafeGuard" (optional): automatic torque monitoring and control system for changing filling levels

- "streisal SafeBox" (optional): Vibration monitor

- Shear-pin coupling as the final predetermined breaking point

MAXIMUM CIRCULATING RATE IN CONCRETE AND STEEL TANKS

Slow-running large-propeller agitators of the Biobull® type enable large quantities of fluid to be circulated in tanks with largely constant fill levels.

They are used above all in biogas generation and in other applications with difficult substrates (fibrous constituents, maximum dry matter contents, etc.). The maximum medium temperature is 60 °C.

By means of an external agitator column, the agitator can also be used in steel tanks of different shapes and sizes: The forces and moments are not transferred to the tank wall, but into the foundation.

POTENTIALLY EXPLOSIVE ATMOSPHERES

The agitators are available with various ATEX, IECEx and UL/CSA ignition protection types for use in explosion protection zones 1 or 2.

CONSTANTLY HIGH AGITATING PERFORMANCE

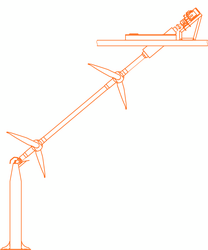

With the agitator shaft installed at an inclined angle and two propellers mounted at different heights, the agitators generate significant hydraulic performance with horizontal and vertical flow components. The substrate can flow in without obstruction because the agitating elements are not covered by any obstructive built-in components. The design of the propeller shape, the large hub diameter and smooth, tangential transition to the propeller blade prevent material from wrapping itself around the blades.

LOWEST SELF-GENERATED ELECTRICITY REQUIREMENT

The propeller geometry with its three dimensional profile has been optimised in the fluid mechanics laboratory; this and the large propeller diameters combined with low speeds of rotation mean the agitators generate maximum thrust while drawing very little power. As a result, energy and operating costs are significantly lower!

EASE OF SERVICING

Important wearing parts are mounted externally and are therefore easy to access for maintenance and servicing. For example, there is no need for the container roof (gas accumulator) to be opened regularly in biogas plants. The agitator shaft is sealed by a gas-tight siphon seal with contactless operation.

HIGH RELIABILITY AND LONG SERVICE LIFE

The streisal Biobull® has been available on the market for 30 years, and the first models are still in use. This means we can truly validate its long service life!