Low-speed

submersible agitators ATP/BTP

TECHNICAL PROPERTIES

| Power range | 1.5 – 11 kW |

|---|---|

| Mains frequency | 50 or 60 Hz |

| Axis thrust | up to 4,000 N |

| Circulating rate | up to 10,829 m³/h |

| Propeller diameter | up to 2,650 mm |

| Coolant/medium temperature | max. 60 °C |

| Mechanical seal | SiC/SiC pairing |

| Immersion depth | max. 20 m |

TECHNICAL SPECIFICATIONS

Technical specifications: ATP

| Type | Power rating | Current rating | Propeller speed | Axial thrust | Circulating rate * |

|---|---|---|---|---|---|

| kW (P2) | A | rpm | N | m³/h | |

| ATP 16 | 1.5 | 3.55 | 22 | 800 | 5,347 |

| ATP 26 | 2.2 | 5.1 | 27 | 1,650 | 6,955 |

| ATP 34 | 3 | 5.9 | 26 | 1,900 | 8,241 |

| ATP 44 | 4 | 7.8 | 33 | 2,900 | 9,220 |

| ATP 54 | 5.5 | 10.7 | 38 | 3,500 | 10,129 |

| ATP 74 | 7.5 | 14.6 | 41 | 4,000 | 10,829 |

| Motor 400 V, IE2 (IE3 can be selected), rated frequency 50 Hz, index of protection IP 68 Energy-saving motors have higher inrush currents due to their design! |

* Circulating rate according to ISO 21630:2007 |

Technical specifications: BTP

| Type | Power rating | Current rating | Propeller speed | Axial thrust | Circulating rate * |

|---|---|---|---|---|---|

| kW (P2) | A | rpm | N | m³/h | |

| BTP 74 | 7.5 | 14.6 | 55 | 2,400 | 4,893 |

| BTP 114 ** | 11 | 21 | 55 | 3,200 | 6,053 |

| Motor 400 V, IE2 (IE3 can be selected), rated frequency 50 Hz, index of protection IP 68 Energy-saving motors have higher inrush currents due to their design! |

* Circulating rate according to ISO 21630:2007 ** Energy efficiency class IE1 |

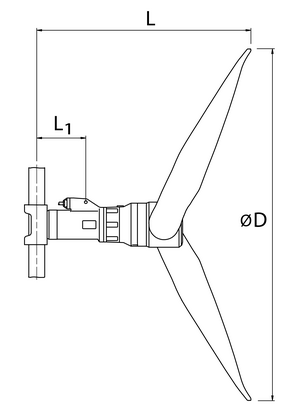

DIMENSIONS AND WEIGHTS

| Type | D | L | L 1 | Weight |

|---|---|---|---|---|

| mm | mm | mm | kg * | |

| ATP 16 | 2,650 | 1,700 | 381 | 295 |

| ATP 26 | 2,400 | 1,630 | 381 | 295 |

| ATP 34 | 2,650 | 1,700 | 381 | 300 |

| ATP 44 | 2,400 | 1,630 | 381 | 300 |

| ATP 54 | 2,400 | 1,630 | 381 | 305 |

| ATP 74 | 2,400 | 1,630 | 381 | 310 |

| BTP 74 | 1,400 | 1,375 | 381 | 280 |

| BTP 114 | 1,500 | 1,375 | 381 | 292 |

* Agitator without carriage

MATERIALS

| Housing | GG25 |

|---|---|

| Seal holder | Stainless steel 1.4301 (V2A), optionally stainless steel 1.4571 (V4A) |

| Connection elements | Stainless steel 1.4301 (V2A) |

| BTP propeller | Stainless steel 1.4301 (V2A) |

| ATP propeller | High-strength, wear-resistant polymer with steel core |

| Propeller shaft | 1.7225 (not in contact with medium) |

| Mechanical seals | Silicon carbide |

| Carriage | Stainless steel 1.4301 (V2A), optionally stainless steel 1.4571 (V4A) |

| Corrosion protection | lnertol Poxitar for standard applications Ceramic coating or the like for aggressive media, or according to customer request |

SAFETY

- For use in potentially explosive atmospheres, ATP/BTP submersible agitators are available with the "pressure-tight encapsulation" ignition protection type (Ex db) according to ATEX and IECEx (zones 1 and 2).

- Temperature monitoring in the motor winding

- Monitoring of the seal system by "streisal Toplimiter" leakage probe in tandem version, i.e. with two mechanical seals and oil chamber on the inlet side

LOTS OF THRUST WITH LITTLE ENERGY

Slow-running submersible agitators of the ATP/BTP type enable large quantities of fluid to be circulated gently. With large diameters and low speeds, these agitators generate maximum thrust with the smallest possible use of energy or electricity. By combining different motors, gearboxes and propeller types/sizes, it is possible to offer submersible motor agitators with the appropriate performance for a wide range of applications: flow generation, circulating, suspension of solids such as in water treatment, process technology, etc.

HARSHEST AMBIENT CONDITIONS

For use in potentially explosive atmospheres, submersible motor agitators in the ATP/BTP series are available in the "pressure-tight encapsulation" ignition protection type II 2G Ex db ib h IIA T3 Gb according to ATEX and IECEx. The maximum medium temperature is 60 °C.

LOWEST SELF-GENERATED ELECTRICITY REQUIREMENT

The use of propellers with optimum hydraulic design, different gear unit ratios and high-efficiency motors (1E2 and IE3 according to IEC 60034-30) achieves maximum overall efficiency.

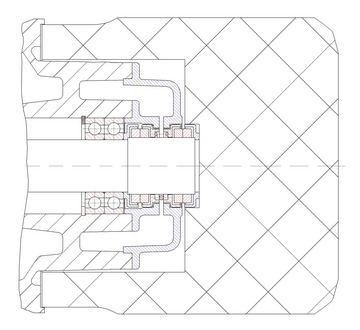

MECHANICAL SEAL SYSTEM

It has been shown in practice that reliability and durability of shaft seals are decisive criteria for trouble-free operation. The unique seal system from streisal offers a range of advantages:

- Two highly wear-resistant silicon carbide mechanical seals (tandem version)

- Mechanical seals are protected by being mounted in a stainless steel holder

- Spring elements on the inside, not in contact with the medium

OPTIMALLY EFFECTIVE PERFORMANCE

With large propeller diameters and low speeds, these submersible agitators develop maximum thrust. The flexible positioning and alignment means that the flow direction can be adapted to the particular tank shape. The self-cleaning propeller shape ensures a constantly high agitating effect and operation without vibration, even when the medium contains fibres.